Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

-

Hey All! Lately there has been more and more scammers on the forum board. They register and replies to members requests for guns and/or parts or other things. The reply contains a gmail or hotmail address or similar ”anonymous” email addresses which they want you to reply to. DO NOT ANSWER ANY STRANGE MESSAGES! They often state something like this: ”Hello! Saw your post about purchasing a stock for a Safari. KnuckleheadBob has one. Email him at: [email protected]” If you receive any strange messages: Check the status of whoever message you. If they have no posts and signed up the same day or very recently, stay away. Same goes for other members they might refer to. Check them too and if they are long standing members, PM them and ask if the message is legit. Most likely it’s not. Then use the report function in each message or post so I can kick them out! Beware of anything that might seem fishy! And again, for all of you who registered your personal name as username, please contact me so I can change it to a more anonymous username. You’d be surprised of how much one can find out about a person from just a username on a forum such ad our! All the best! And be safe! Jim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7x33 sako build

- Thread starter topgear

- Start date

Hi, unfortunately I was unable to make it down to the show. I am interested in what was there on show, rifles, ammo bits n pieces?

Was there much public interest in the stand, I hope NOT Sako prices are high enough over here!?

Is there another show planned for later in the year? There used to be 2 shows per year.

Its great to hear so far some positive feedback from some of the forum members that attended.

Regards, Jay

Was there much public interest in the stand, I hope NOT Sako prices are high enough over here!?

Is there another show planned for later in the year? There used to be 2 shows per year.

Its great to hear so far some positive feedback from some of the forum members that attended.

Regards, Jay

sraaw

Well-Known Member

L46 7x33 build

Well thanks to the generosity of member TopGear, my 7x33 build has come to fruition! As many here will appreciate it's becoming more and more difficult to secure a 7x33 of original manufacture, so a few Australian members decided we would build our own, rather than wait for one to happen along. Yes I know, now that I've done it I am expecting an original to turn up any time now…..

My plan was based around a L46 .222 Rem rifle I had sold to a workmate a couple of years ago that I knew was in good shape. A deal was done whereby I swapped the L46 for a A1 in similar condition I bought off my brother. Once done I ordered a Sako Vixen profile chrome molly barrel from TSE (Brisbane) with a 1:10 RH twist. This, I understand this is the longest twist they produce, as standard for a .284 barrel, otherwise I would have opted for a 1:12 or similar twist.

At this point Topgear was kind enough to ship his unused PTG reamer to me to enable the chamber to be cut by my local smith.

Well I am pleased to say all went well and the barrel was chambered and fitted a couple of weeks ago and I was able to pick up the finished product just after Easter. The gunsmith fitted both rear and fore sights to the replacement barrel. The barrel was drilled and tapped to fit these as I wanted the flexibility to remove them if need be depending on usage requirements. The foresight came from my first ever Sako, a L461 that I purchased new in 1977. The barrel this has since been replaced and no longer in use so was available. The rear ramp sight came from a Bofors .243 barrel I spotted sticking out of a bucket of old barrels in my gunsmiths workshop a couple of months earlier. Unfortunately the rear sight interfered with the mounting of the scope, so has since been removed and plug screws installed in the holes in the barrel.

The scope is a Leupold VXII 3-9x40 mounted in Conetrol rings/bases. I used the Custom rings which are gloss to match the old Sako and because they are easier to install because they have the additional screws that "help to hold things together" while you are working with them.

See some pics of the completed setup.

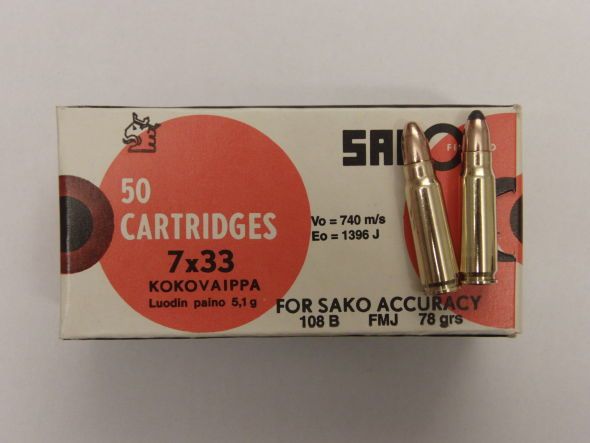

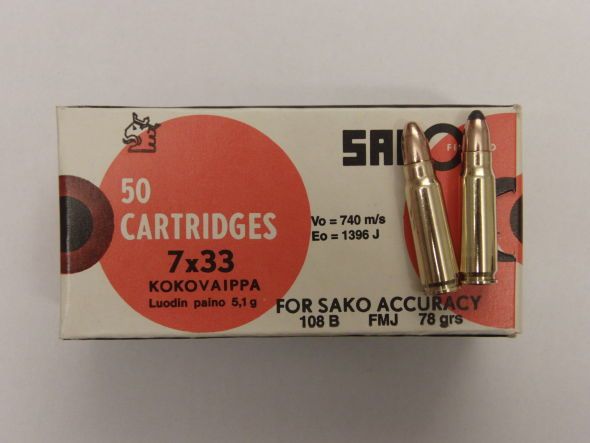

In the mean time I had secured 100 x Sako factory rounds (78gn Gamehead) which Baretta have recently had for sale in Australia. I managed to find time to take her to the range today for zeroing and barrel break -in. Conditions were a little breezy so I am more than satisfied with the initial results.

The next challenge will be to sort out a source of projectiles for when the factory ammo runs out. I am currently looking at the possibility of swaging some 90 gn .30 cal pistol projectiles to suit, however will let you know how things progress on this front.

My plan now is to hunt with this setup. Mainly small animals such as wild cats /dogs but also wild pigs and small deer such as Chital and maybe even Fallow.

Once again thanks to Topgear for his generosity!

Cheers,

Well thanks to the generosity of member TopGear, my 7x33 build has come to fruition! As many here will appreciate it's becoming more and more difficult to secure a 7x33 of original manufacture, so a few Australian members decided we would build our own, rather than wait for one to happen along. Yes I know, now that I've done it I am expecting an original to turn up any time now…..

My plan was based around a L46 .222 Rem rifle I had sold to a workmate a couple of years ago that I knew was in good shape. A deal was done whereby I swapped the L46 for a A1 in similar condition I bought off my brother. Once done I ordered a Sako Vixen profile chrome molly barrel from TSE (Brisbane) with a 1:10 RH twist. This, I understand this is the longest twist they produce, as standard for a .284 barrel, otherwise I would have opted for a 1:12 or similar twist.

At this point Topgear was kind enough to ship his unused PTG reamer to me to enable the chamber to be cut by my local smith.

Well I am pleased to say all went well and the barrel was chambered and fitted a couple of weeks ago and I was able to pick up the finished product just after Easter. The gunsmith fitted both rear and fore sights to the replacement barrel. The barrel was drilled and tapped to fit these as I wanted the flexibility to remove them if need be depending on usage requirements. The foresight came from my first ever Sako, a L461 that I purchased new in 1977. The barrel this has since been replaced and no longer in use so was available. The rear ramp sight came from a Bofors .243 barrel I spotted sticking out of a bucket of old barrels in my gunsmiths workshop a couple of months earlier. Unfortunately the rear sight interfered with the mounting of the scope, so has since been removed and plug screws installed in the holes in the barrel.

The scope is a Leupold VXII 3-9x40 mounted in Conetrol rings/bases. I used the Custom rings which are gloss to match the old Sako and because they are easier to install because they have the additional screws that "help to hold things together" while you are working with them.

See some pics of the completed setup.

In the mean time I had secured 100 x Sako factory rounds (78gn Gamehead) which Baretta have recently had for sale in Australia. I managed to find time to take her to the range today for zeroing and barrel break -in. Conditions were a little breezy so I am more than satisfied with the initial results.

The next challenge will be to sort out a source of projectiles for when the factory ammo runs out. I am currently looking at the possibility of swaging some 90 gn .30 cal pistol projectiles to suit, however will let you know how things progress on this front.

My plan now is to hunt with this setup. Mainly small animals such as wild cats /dogs but also wild pigs and small deer such as Chital and maybe even Fallow.

Once again thanks to Topgear for his generosity!

Cheers,

Hi Sraaw,

Great story and pics, great looking outfit, something to be really proud of.

The group look good too, I am sure it will make a great small game outfit. Looking forward to seeing the first pic with its first head of small game with the little rifle

as the star attraction.

Jay

Great story and pics, great looking outfit, something to be really proud of.

The group look good too, I am sure it will make a great small game outfit. Looking forward to seeing the first pic with its first head of small game with the little rifle

as the star attraction.

Jay

sraaw

Well-Known Member

Thanks all for the kind words.

For those interested I did crony the 15 shots fired at the range yesterday. The average velocity went 2,471 fps with an extreme spread of a tad over 70 fps.

I am happy to be able to achieve a velocity over the 2400 fps mark with the 78 grainers.

Since posting yesterday I tried to use my new Simplex dies to deprime and resize the fired cases. This didn't go so well as I found that I was unable to run a case up into the FL die. I actually managed to get the first one stuck even though it wouldn't go to within 8-10mm of where it should, and then managed to pull part of the rim off the case, trying to remove it from the die.

I plan to call Simplex on Monday to see what they think. I will probably send them the reamer details so they can compare with the measurements they use for their dies. It will be interesting to hear what they have to say.

If all else fails I will probably look into converting the FL die into a neck size die, as I doubt I would need to fully FL resize anyway.

Deersako - My smith used the reamer as it came, so I assume the chamber and throat is cut to the dimensions shown in the drawing included in Topgear's first post of this thread. It will be interesting to see if this enables longer projectiles to be used, such as the 100 and 110 grain varmint projectiles available from Sierra and Speer, without having to seat them too deep.

I have tweaked (opened up) the lips of one mag so far and also scolloped the front of the box to enable the projectile to come forward and engage the ramp that guides it into the chamber during the feeding operation. This has been quite successful, given the limited testing done so far. I can't say that feeding is as smooth as silk, but it is satisfactory and I hope will improve further with some more refinement.

More to follow as things develop further.

Cheers

For those interested I did crony the 15 shots fired at the range yesterday. The average velocity went 2,471 fps with an extreme spread of a tad over 70 fps.

I am happy to be able to achieve a velocity over the 2400 fps mark with the 78 grainers.

Since posting yesterday I tried to use my new Simplex dies to deprime and resize the fired cases. This didn't go so well as I found that I was unable to run a case up into the FL die. I actually managed to get the first one stuck even though it wouldn't go to within 8-10mm of where it should, and then managed to pull part of the rim off the case, trying to remove it from the die.

I plan to call Simplex on Monday to see what they think. I will probably send them the reamer details so they can compare with the measurements they use for their dies. It will be interesting to hear what they have to say.

If all else fails I will probably look into converting the FL die into a neck size die, as I doubt I would need to fully FL resize anyway.

Deersako - My smith used the reamer as it came, so I assume the chamber and throat is cut to the dimensions shown in the drawing included in Topgear's first post of this thread. It will be interesting to see if this enables longer projectiles to be used, such as the 100 and 110 grain varmint projectiles available from Sierra and Speer, without having to seat them too deep.

I have tweaked (opened up) the lips of one mag so far and also scolloped the front of the box to enable the projectile to come forward and engage the ramp that guides it into the chamber during the feeding operation. This has been quite successful, given the limited testing done so far. I can't say that feeding is as smooth as silk, but it is satisfactory and I hope will improve further with some more refinement.

More to follow as things develop further.

Cheers

Last edited:

L-46

Well-Known Member

A great result!! A really nice looking rifle.

I would think that the die set May be ok. No doubt it may be a few thou smaller than desired for your chamber.

Did you use the old thick case lube on the tray? not the newer spray can.

It can take a new die set a few rounds and some lube to penetrate and enable the die to work as intended

when new they can be dry and far from polished inside.

L-46

I would think that the die set May be ok. No doubt it may be a few thou smaller than desired for your chamber.

Did you use the old thick case lube on the tray? not the newer spray can.

It can take a new die set a few rounds and some lube to penetrate and enable the die to work as intended

when new they can be dry and far from polished inside.

L-46

Last edited:

alpine hunter

Well-Known Member

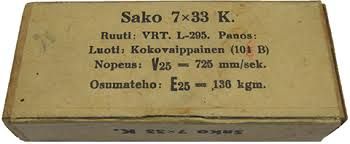

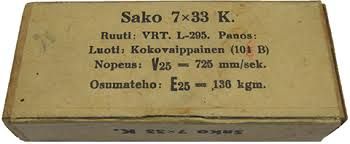

Susanna. I don't have any diferent to your 7x33 boxes but I do have some images I found on the net that show some different boxes. The first is a variation of the 50 cartridges box. I also have a very poor quality picture of one similar with a big paper label that looks like it could be factory.

The second is obviously different and matches the plain brown paper style of other calibre boxes.

The third shows a variation of the red and blue box. Note the "BULLET WEIGHT 77 GRAIN" line.

The second is obviously different and matches the plain brown paper style of other calibre boxes.

The third shows a variation of the red and blue box. Note the "BULLET WEIGHT 77 GRAIN" line.

alpine hunter

Well-Known Member

On the subject of 7x33 builds, I have a project in mind as well. Mine is more of a modern build probably based on a 461 action. The plan is a light weight compact carbine to be used as an easy carry around rifle for anything from foxes through wild dogs, goats, pigs and smaller deer. Synthetic stock (or slimline laminate) and stainless barrel to suit a very practical purpose.

Don't have the donor action yet or a strict timeline on it! Just purchased a L46 fullwood 222 so the 7x33 project is set back a bit. Also got a semi auto 12ga to buy some time soon as well. AND a new Sako A7 Roughtech to upgrade my 300WSM!! Somehow I manage to go from a single idea in my mind and no other planned purchases to a list waiting for the right opportunity.

This topic is great info for when I get going on my build.

I was also thinking that the Aussie Custom Projectiles could be a good source for a mono-metal HP hunting bullet in 7x33. They seem to be getting very good results in other calibres. There is also the option to custom order different hardness of the metal - soft, medium or hard. The soft option might be best for the 7x33.

Don't have the donor action yet or a strict timeline on it! Just purchased a L46 fullwood 222 so the 7x33 project is set back a bit. Also got a semi auto 12ga to buy some time soon as well. AND a new Sako A7 Roughtech to upgrade my 300WSM!! Somehow I manage to go from a single idea in my mind and no other planned purchases to a list waiting for the right opportunity.

This topic is great info for when I get going on my build.

I was also thinking that the Aussie Custom Projectiles could be a good source for a mono-metal HP hunting bullet in 7x33. They seem to be getting very good results in other calibres. There is also the option to custom order different hardness of the metal - soft, medium or hard. The soft option might be best for the 7x33.

sraaw

Well-Known Member

Hi all,

Just an update on how things have progressed since my last post. L46 proved to be correct and the use of a more effective lube saw the Simplex FL die functioning with no issues.

Next was the projectile issue needing to be resolved, to make the whole reloading aspect feasible. First I have loaded some test loads based on 110 gn Sierra Varminter HP projectiles, pushed by AR2205, using a starting load of 13.4 gn, then stepping up by 0.3 gn up to 14.3 gn, if pressure indications allow. These feed nicely through the .222 Rem magazine by the way.

In addition I have been looking into options to produce a lighter projectile a little closer to the factory 78 grainers that will enable a little more velocity than the Sierra 110s. To achieve this I ended up getting a Lee .284 projectile sizing die, through which I planned to push 85gn .30 cal Sierra RN projectiles through. This was done using my Redding C frame press which struggled to produce the power required. Additionally the resultant projectiles were less than satisfactory, with some copper jacket migrating down past the base of most of the resized projectiles. In order to make things easier on projectiles and the press I had my gunsmith make up an intermediate swaging die of around .295 Dia. Initial testing using this two stage swaging process has beed quite successful. The result is a longer projectile of the required diameter. The only real issue with the final product is the lead core ends up protruding forward about 1mm at the nose. See pic below showing the .30 cal projectile (right to left) and then the two swaging stages.

I have discussed this with my gunsmith, who advises it would be a simple matter of making up a concave punch to reshape the nose of the projectiles while they are still held in the second swaging die. This would add a third stage to the resizing process.

At this point I intend to test the projectiles in their current state, to see how they shoot in my rifle, remembering my aim is to produce hunting/plinking projectiles for my own every day use, rather than a match quality product. If after testing I need more accuracy I will go down the path of reshaping the points to see if it helps.

I am busy this week end so range testing will have to wait until the following weekend.

In the mean time I am hoping someone here who has Quickload software might be able to assist with a starting load for the 7x33 using AR2205 and these 85 grainers? Also, confirmation that the starting load of 13.4 is an appropriate place to start off from for the 110 grainers?

Cheers,

Just an update on how things have progressed since my last post. L46 proved to be correct and the use of a more effective lube saw the Simplex FL die functioning with no issues.

Next was the projectile issue needing to be resolved, to make the whole reloading aspect feasible. First I have loaded some test loads based on 110 gn Sierra Varminter HP projectiles, pushed by AR2205, using a starting load of 13.4 gn, then stepping up by 0.3 gn up to 14.3 gn, if pressure indications allow. These feed nicely through the .222 Rem magazine by the way.

In addition I have been looking into options to produce a lighter projectile a little closer to the factory 78 grainers that will enable a little more velocity than the Sierra 110s. To achieve this I ended up getting a Lee .284 projectile sizing die, through which I planned to push 85gn .30 cal Sierra RN projectiles through. This was done using my Redding C frame press which struggled to produce the power required. Additionally the resultant projectiles were less than satisfactory, with some copper jacket migrating down past the base of most of the resized projectiles. In order to make things easier on projectiles and the press I had my gunsmith make up an intermediate swaging die of around .295 Dia. Initial testing using this two stage swaging process has beed quite successful. The result is a longer projectile of the required diameter. The only real issue with the final product is the lead core ends up protruding forward about 1mm at the nose. See pic below showing the .30 cal projectile (right to left) and then the two swaging stages.

I have discussed this with my gunsmith, who advises it would be a simple matter of making up a concave punch to reshape the nose of the projectiles while they are still held in the second swaging die. This would add a third stage to the resizing process.

At this point I intend to test the projectiles in their current state, to see how they shoot in my rifle, remembering my aim is to produce hunting/plinking projectiles for my own every day use, rather than a match quality product. If after testing I need more accuracy I will go down the path of reshaping the points to see if it helps.

I am busy this week end so range testing will have to wait until the following weekend.

In the mean time I am hoping someone here who has Quickload software might be able to assist with a starting load for the 7x33 using AR2205 and these 85 grainers? Also, confirmation that the starting load of 13.4 is an appropriate place to start off from for the 110 grainers?

Cheers,

L-46

Well-Known Member

Sraaw,

A really great post!

The fun of these projects is the journey, Thanks for sharing.

You are really making progress with the projectiles, so point them up and let us know how they shoot.

As for a starting load, for your 'customly modded' 85's, i would start 15% less than the 78 gn load and go up from there. Load one of each charge to start.

I have played around with Custom Wild cats and lots of Ackley cartridges. What i do now, with unknown case and bullet combinations is start low and load one round only, in .3 jumps. When a maximum load is found, any loaded unfired cases can be easily pulled,

You can get an idea of your final load too, if you have a chrony at this early stage. if things go to plan you can finish your load development in under 20 shots!

I draw a texta line across my target paper and put a verticle line every inch or so along this line, as aim points. I then make sure I place the target and the texta line horizontal with a spirit level on the target frame. Just got a free level app on my phone!

Starting from one side, I fire 1 shot at each dot along the paper, and you will see the holes appear in a wave above and below the line. This is an indication of the barrel harmonics. Make sure to write down the velocity at each powder charge, so you can refer back later, and draw a drop chart. Your most consistent load will be at the top or bottom of this wave pattern. The more accurate the rifle, the easier the pattern is to see!

When you approach the maximum pressure /powder charge you are happy with, go to the closest wave point, or powder 'Node' and go up and down in .1 grain increments to find your sweet spot. I usually load 3 cartridges of each powder charge at this point, so a group is formed. The powder node or 'accuracy' will appear in less than 1 grain intervals as a general rule.

When you have chosen your load take note of your velocity to be able to calculate a drop chart and also compare future powder lots.

L-46

A really great post!

The fun of these projects is the journey, Thanks for sharing.

You are really making progress with the projectiles, so point them up and let us know how they shoot.

As for a starting load, for your 'customly modded' 85's, i would start 15% less than the 78 gn load and go up from there. Load one of each charge to start.

I have played around with Custom Wild cats and lots of Ackley cartridges. What i do now, with unknown case and bullet combinations is start low and load one round only, in .3 jumps. When a maximum load is found, any loaded unfired cases can be easily pulled,

You can get an idea of your final load too, if you have a chrony at this early stage. if things go to plan you can finish your load development in under 20 shots!

I draw a texta line across my target paper and put a verticle line every inch or so along this line, as aim points. I then make sure I place the target and the texta line horizontal with a spirit level on the target frame. Just got a free level app on my phone!

Starting from one side, I fire 1 shot at each dot along the paper, and you will see the holes appear in a wave above and below the line. This is an indication of the barrel harmonics. Make sure to write down the velocity at each powder charge, so you can refer back later, and draw a drop chart. Your most consistent load will be at the top or bottom of this wave pattern. The more accurate the rifle, the easier the pattern is to see!

When you approach the maximum pressure /powder charge you are happy with, go to the closest wave point, or powder 'Node' and go up and down in .1 grain increments to find your sweet spot. I usually load 3 cartridges of each powder charge at this point, so a group is formed. The powder node or 'accuracy' will appear in less than 1 grain intervals as a general rule.

When you have chosen your load take note of your velocity to be able to calculate a drop chart and also compare future powder lots.

L-46

topgear

Sako-addicted

Great work on the projectiles. See below for a rough indication. All I have done is change the sako 78grn projectile profile to 85 grn in weight. They look similar shapes so it may give you an idea of starting points and what to expect.

I can't find the sierra 110grn listed? are you sure you don't mean 100grn sierra?

I can't find the sierra 110grn listed? are you sure you don't mean 100grn sierra?

Attachments

sraaw

Well-Known Member

Thanks Topgear, the data from Quickload is a big help. You are correct, they are the Sierra 100gn varmints. I got mixed up with the Speer 110s which I have as well. I'll pull the 14.3 loads and redo with 13.0 as a starting load with the 100 gn Sierras. I will try to get to the range in a week to test them out.

Latest posts

-

-

-

-

-

-

-

-

-

P54 Just picked up a P54, who else has one

- Latest: paulsonconstruction

-