Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

-

Hey All! Lately there has been more and more scammers on the forum board. They register and replies to members requests for guns and/or parts or other things. The reply contains a gmail or hotmail address or similar ”anonymous” email addresses which they want you to reply to. DO NOT ANSWER ANY STRANGE MESSAGES! They often state something like this: ”Hello! Saw your post about purchasing a stock for a Safari. KnuckleheadBob has one. Email him at: [email protected]” If you receive any strange messages: Check the status of whoever message you. If they have no posts and signed up the same day or very recently, stay away. Same goes for other members they might refer to. Check them too and if they are long standing members, PM them and ask if the message is legit. Most likely it’s not. Then use the report function in each message or post so I can kick them out! Beware of anything that might seem fishy! And again, for all of you who registered your personal name as username, please contact me so I can change it to a more anonymous username. You’d be surprised of how much one can find out about a person from just a username on a forum such ad our! All the best! And be safe! Jim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

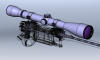

Digital 3D Sako L579

- Thread starter tilleyman

- Start date

Branxhunter

Well-Known Member

Impressive work Tilleyman. The bloom on the scope lenses looks terrific!

tilleyman

Well-Known Member

Thanks...Fantastic work! What program do you use?

Mix of CATIA V5 and Solidworks, with some rendering done in Rhino Flamingo.

Been working through Jeremy Birn's excellent reference Digital Lighting and Rendering (Second Edition)

Last edited:

Foxhunter223

Well-Known Member

Who would be brave enough to run a gold plated bolt through an action ? Even though it sure looks wonderful.

Pete

Pete

tilleyman

Well-Known Member

Yes would be very practical for a firearm if you can get past the bling factor!In the real world, you could get an almost-gold look with Titanium Nitride (TiN), a super-hard coating used for drills and other cutting tools.

Seems a few suppliers are now offering TiN coating for firearm parts...

https://brazenfirearms.com/collections/tin-coatings

https://www.titaniumgun.com/coatings

tilleyman

Well-Known Member

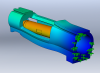

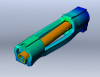

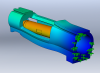

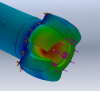

OK having made a digital 3D L579 model, now it's time to blow it up... a cold rainy Sunday here and 'idle hands are the Devil's tools'

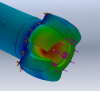

I'd always heard about the so-called 'inherent weakness' of the Mauser/Sako split LH bolt lug vs others like the Remington 700 so a simplified CAD model was created for an FEA study. Barrel was excluded and the receiver fixed at its front face to simplify 3D meshing.

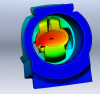

A massive overload was then placed on the boltface when locked into the receiver to see the failure mode.

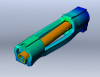

A separate study was then done on the bolt, with a restraint on the lug engagement faces and the same overload placed on the bolt face.

There's a few studies around which help calculate the bolt backthrust... a typical .308Win is around 6,300 psi so I just kept on raising the pressure well above any that would ever be found in real life to identify areas of theoretical problems... ten times normal.

https://riflebarrels.com/a-look-at-bolt-lug-strength/

The results are interesting... and indicate any major issue is not so much with the split lug design (though each half twists more than the solid lug) far more the culprit seems to be the cutout for the extractor and spring at the base of the solid bolt lug.

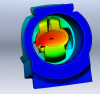

Note how these cut away areas lead the bolt body to cant off axis under extreme load into the receiver raceway, and the bowed receiver rail on RHS.

These results are of course greatly exaggerated and in no way suggest Sako L-A actions are weak... but are interesting to see, if only to help settle an old argument!

I'd always heard about the so-called 'inherent weakness' of the Mauser/Sako split LH bolt lug vs others like the Remington 700 so a simplified CAD model was created for an FEA study. Barrel was excluded and the receiver fixed at its front face to simplify 3D meshing.

A massive overload was then placed on the boltface when locked into the receiver to see the failure mode.

A separate study was then done on the bolt, with a restraint on the lug engagement faces and the same overload placed on the bolt face.

There's a few studies around which help calculate the bolt backthrust... a typical .308Win is around 6,300 psi so I just kept on raising the pressure well above any that would ever be found in real life to identify areas of theoretical problems... ten times normal.

https://riflebarrels.com/a-look-at-bolt-lug-strength/

The results are interesting... and indicate any major issue is not so much with the split lug design (though each half twists more than the solid lug) far more the culprit seems to be the cutout for the extractor and spring at the base of the solid bolt lug.

Note how these cut away areas lead the bolt body to cant off axis under extreme load into the receiver raceway, and the bowed receiver rail on RHS.

These results are of course greatly exaggerated and in no way suggest Sako L-A actions are weak... but are interesting to see, if only to help settle an old argument!

Last edited:

bloorooster

The Old Hippie

Amazing!

I have always understood that the Sako action is a very strong action, and for this reason it is a popular choice for a build. With this being said , I have also understood that the action can warp if not properly bedded or even over tightened. I suppose this would be true with any action that was not properly bedded or supported.

I wonder if this warping could be the culprit in as far as recent reports of sticky bolt cycling, or poor trigger/ sear engagements?

I always felt that the stock inlets would give out or otherwise distort with over tightening , simply because the wood can be compressed easily by the clamping pressure of the much harder steel action and bottom metal.

Action strength is measured in psi or cup ? .308 win has SAMMI industry max rating of 52,000 cup, not sure how to equate cup to psi.

I have been told that a Sako action will tolerate much higher pressures, but I wonder how much more?

Surely , it seems almost impossible to over load a cartridge to a level that would cause this kind of structural failure.

I commend Brother Tillyman, for this work, which at first , to me , was just computer art or animations.

I apologize for the oversight , as this 21st century scientific application sinks into my 20th century brain!

Awesome work!

Bloorooster ..the old Hippie

I have always understood that the Sako action is a very strong action, and for this reason it is a popular choice for a build. With this being said , I have also understood that the action can warp if not properly bedded or even over tightened. I suppose this would be true with any action that was not properly bedded or supported.

I wonder if this warping could be the culprit in as far as recent reports of sticky bolt cycling, or poor trigger/ sear engagements?

I always felt that the stock inlets would give out or otherwise distort with over tightening , simply because the wood can be compressed easily by the clamping pressure of the much harder steel action and bottom metal.

Action strength is measured in psi or cup ? .308 win has SAMMI industry max rating of 52,000 cup, not sure how to equate cup to psi.

I have been told that a Sako action will tolerate much higher pressures, but I wonder how much more?

Surely , it seems almost impossible to over load a cartridge to a level that would cause this kind of structural failure.

I commend Brother Tillyman, for this work, which at first , to me , was just computer art or animations.

I apologize for the oversight , as this 21st century scientific application sinks into my 20th century brain!

Awesome work!

Bloorooster ..the old Hippie

tilleyman

Well-Known Member

I don’t think you could ever get a .308 cartridge up to this pressure level unless it was filled with a shotgun powder or similar.

However the FEA study does point to some inherent flexibility in the RH lower receiver rail which bowed considerably vs the LHS... possibly this is the area that is warping if the action screws are over tightened?

The Tikka T3 and Sako TRG receivers feature a much more enclosed ejection port, making them far more rigid.

It would be interesting to run a similar FEA study on the Sako 75 three lug bolt but alas I don’t own one!

However the FEA study does point to some inherent flexibility in the RH lower receiver rail which bowed considerably vs the LHS... possibly this is the area that is warping if the action screws are over tightened?

The Tikka T3 and Sako TRG receivers feature a much more enclosed ejection port, making them far more rigid.

It would be interesting to run a similar FEA study on the Sako 75 three lug bolt but alas I don’t own one!

bloorooster

The Old Hippie

True , the TRG and its little sister,TRG-s actions are said to be superior in design.

An episode of bore obstruction would be interesting to run on this program. Can that be synthesized as well?

An episode of bore obstruction would be interesting to run on this program. Can that be synthesized as well?

bloorooster

The Old Hippie

Very interested in that!

Lol..between the two scenarios, I personally would rather see the screw torque/action warp.

Lol..between the two scenarios, I personally would rather see the screw torque/action warp.

tilleyman

Well-Known Member

Very interested in that!

Lol..between the two scenarios, I personally would rather see the screw torque/action warp.

Yes will be keen to see action screw studies too, I know from a benchrest mate that torque levels have a significant effect on his groups hence his use of hex headed screws and an inch-pound torque wrench.

The above FEA results suggest that despite trueing the bolt face to the axis of the receiver, and lapping in the lugs if the load that can be transmitted to those lugs is inherently uneven then only the lower lug is actually doing the majority of the work.

When I get time I will also run the same FEA scenario with the split lug filled in to act as a sort-of comparison to a Rem 700 action with a Sako extractor kit fitted (!).

I like the 'elegant simplicity' of the TRG bolt head design much more than the 85, if anyone has any dimensions I could make up a sketch model and run FEA again.

Maybe three lug designs more evenly support the bolt face load and are inherently more accurate?

Sako changed over all their new designs to three lugs for good reasons, it can't just be for low bolt lift... and now offer a 5-shot MOA accuracy guarantee out of the box.

I note in the Sako factory video (02:48) the one piece forged 85 bolt rough shape is concentrated on the handle end for ease of manufacture vs also forming the bolt lug area for better grain flow and much higher strength. Maybe not required?

Last edited:

From what I have seen the cartridge case head will rupture way before the lugs give away and that's the way it should be in most cases. It's safer to vent the pressure through a hole in the case head with the bolt in place rather than eject the whole bolt potentially to the shooters face. If the vented pressure inside the locking lug recess is high enough it can split the front of the receiver. I have seen some aftermath of a case head rupture, where the receiver is split and barrel is ejected forwards and the shooter is fine for the most part. The bolt remained in place.

Better support for the case head will allow it to stand for higher pressures, but there is always at least the slot for the extractor. @tilleyman can you model brass flow under high pressures? Test different bolt face designs? I wonder what a steel case head might do in this equation.

Better support for the case head will allow it to stand for higher pressures, but there is always at least the slot for the extractor. @tilleyman can you model brass flow under high pressures? Test different bolt face designs? I wonder what a steel case head might do in this equation.

tilleyman

Well-Known Member

Oh for sure the pressures applied in the above studies are WAY above anything you would ever find in real life... purely to investigate the theoretical behavior of the split locking lug design under extreme load... but does enable a potential weak area to be identified quickly as meshing and running each 'what-if' FEA study takes time.

Most modern rifles are designed with gas ports in both the receiver and the bolt to vent excessive pressure safely and Sako is no exception.

The failure modes shown above simply could not occur in real life.

308 Winchester chambered arms in C.I.P. regulated countries are currently proof tested at 519 MPa (75,275 psi) PE piezo pressure, and the study above was conducted at 4150MPa (601,907 psi).

A more realistic scenario would be to run the test with a safety factor of 3 x Proof Pressure so 1557 MPa (225,824 psi) and then work out the cartridge case head thrust to apply to the bolt face from there. On my to-do list...

The brass cartridge case forms a 'flexible bladder' to contain the chamber pressure and would indeed flow into locking lug recesses and extractor cutouts under extreme pressure as seen in several catastrophic rifle failure pics.

Could be modelled but would be complex... and we already know how it will likely behave.

As you say in many real life massive overload cases the receiver is split (or distorted like in my study), the bolt stays in place but the barrel acts as some type of 'fusible plug' and ejects away from the startled shooter after the receiver lets go or the threads shear.

The recent Serbu .50 BMG receiver failure was unfortunately the opposite, Scott from Kentucky Ballistics is a very lucky man!

I removed the barrel and threads from the FEA study for simplicity...

It would be very interesting to test different bolt face designs and locking lug layouts... the results may be rather surprising!

Most modern rifles are designed with gas ports in both the receiver and the bolt to vent excessive pressure safely and Sako is no exception.

The failure modes shown above simply could not occur in real life.

308 Winchester chambered arms in C.I.P. regulated countries are currently proof tested at 519 MPa (75,275 psi) PE piezo pressure, and the study above was conducted at 4150MPa (601,907 psi).

A more realistic scenario would be to run the test with a safety factor of 3 x Proof Pressure so 1557 MPa (225,824 psi) and then work out the cartridge case head thrust to apply to the bolt face from there. On my to-do list...

The brass cartridge case forms a 'flexible bladder' to contain the chamber pressure and would indeed flow into locking lug recesses and extractor cutouts under extreme pressure as seen in several catastrophic rifle failure pics.

Could be modelled but would be complex... and we already know how it will likely behave.

As you say in many real life massive overload cases the receiver is split (or distorted like in my study), the bolt stays in place but the barrel acts as some type of 'fusible plug' and ejects away from the startled shooter after the receiver lets go or the threads shear.

The recent Serbu .50 BMG receiver failure was unfortunately the opposite, Scott from Kentucky Ballistics is a very lucky man!

I removed the barrel and threads from the FEA study for simplicity...

It would be very interesting to test different bolt face designs and locking lug layouts... the results may be rather surprising!

Last edited:

Ah, I didn't realize it was THAT much.above was conducted at 4150MPa (601,907 psi).

Very true.The recent Serbu .50 BMG receiver failure was unfortunately the opposite, Scott from Kentucky Ballistics is a very lucky man!

tilleyman

Well-Known Member

It can but this was just a quick study so I used default settings for 4340 tool steel normalised not hardened to a specific Rockwell level.Ah, I didn't realize it was THAT much.Does the simulation account for hardness? My intuition says the hardened steel could not deform to that point without cracking.

Very true.

I’m not sure exactly what steel or heat treatment Sako used for the L579 action back in the day... it was also supposedly drop-forged which would increase toughness.

So 4340 would be more malleable in the normalised state... without specific material and heat treatment details any FEA study can only be an approximation.